We care about your safety, we care about you!

For anyone at work, avoiding injuries and ill health caused by work should be the main concern. Safety & Health is one of the top commitments to the client, our attitudes and beliefs about health and safety send a powerful message about how seriously we care about it and the relating procedures on the working site, as the real causes of accidents can often be traced back to the decisions of managers and business.

Reecons’ HSE Management System (HSEMS) complies with Vietnam’s legislation and refers to the quality management concept to incorporate into the Project HSE management approach. Utilizing this concept will allow the project to maintain a continual improvement cycle. These improvements are expected to be realized by the reduction of onsite risks in a systematic manner. From this principle, we developed the model of safety training as follows:

- Supervision: supervising job practices to ensure the safety of workers

- Training: conducting safety training through Toolbox Meeting hosted by Safety Department every morning, insisting that everyone complies with company safety policies and rules.

- Resources: providing physical support for workers to work safely, such as tools, supplies, materials.

- Support: hosting monthly safety incentives to build a positive psychosocial work atmosphere so that employees do not work under undue stress.

There are many risks caused during construction works. Typically come from working from height with no fall protection; poor housekeeping; electrical & extension cords, confined spaces, etc. Understanding that workers won’t inherently know they have to do something a certain way, it’s up to us to appropriately train workers on our safety protocols. Our training begins upon hiring the new workers, provides an introduction to occupational safety and health, including hazard recognition to monitor and supervise the workers to check whether they’re applying it appropriately.

Bad Safety Practices

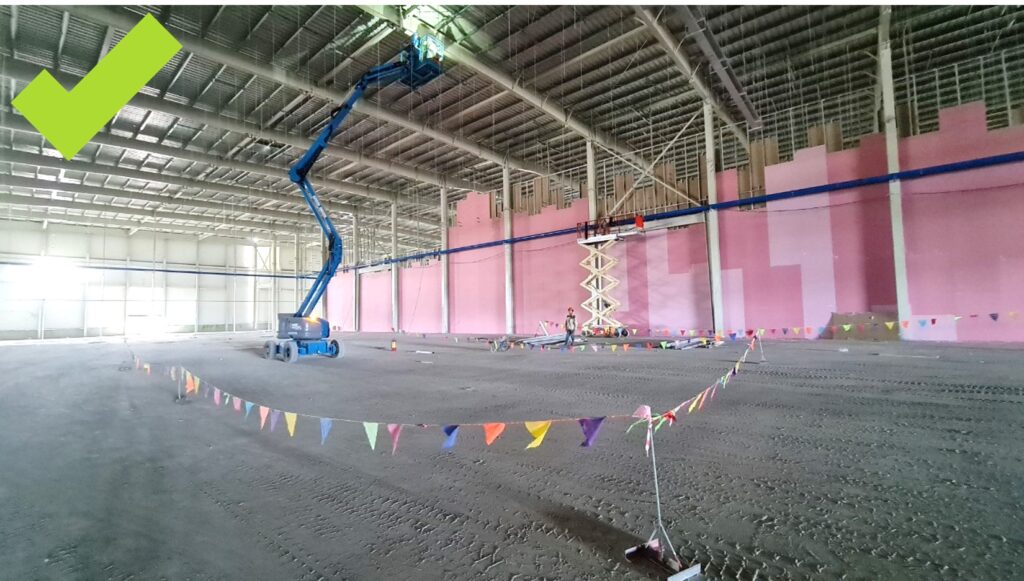

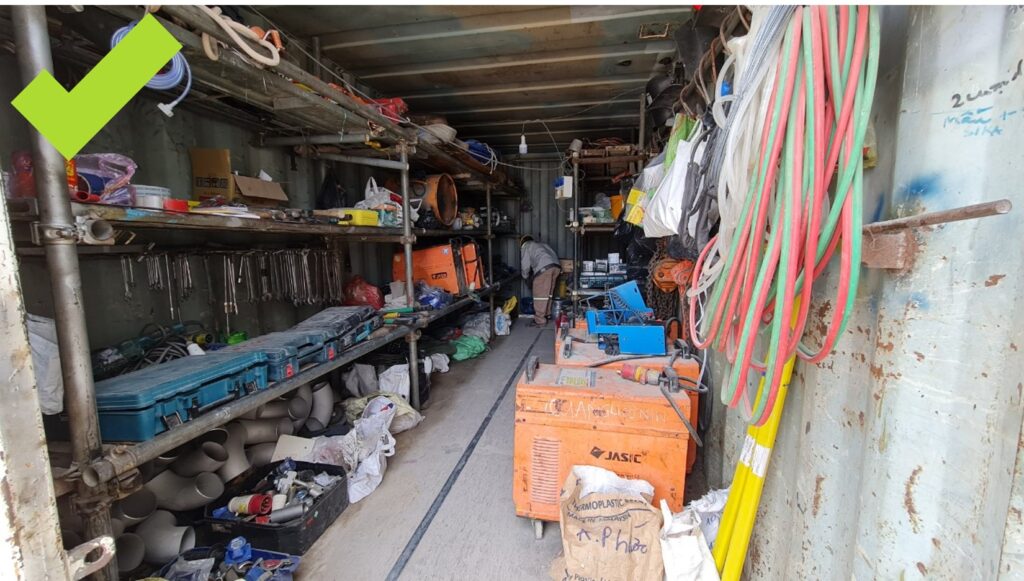

Good Safety Practices

Through the evidence of safety research and our practical experience, it is shown that successful safety management contributes in many ways to the bottom line. Not only will there be a reduction in workplace incidents, but there will also be an improved safety culture, cost savings, and quality and productivity improvements. That contributes to our overall goals being achieved.